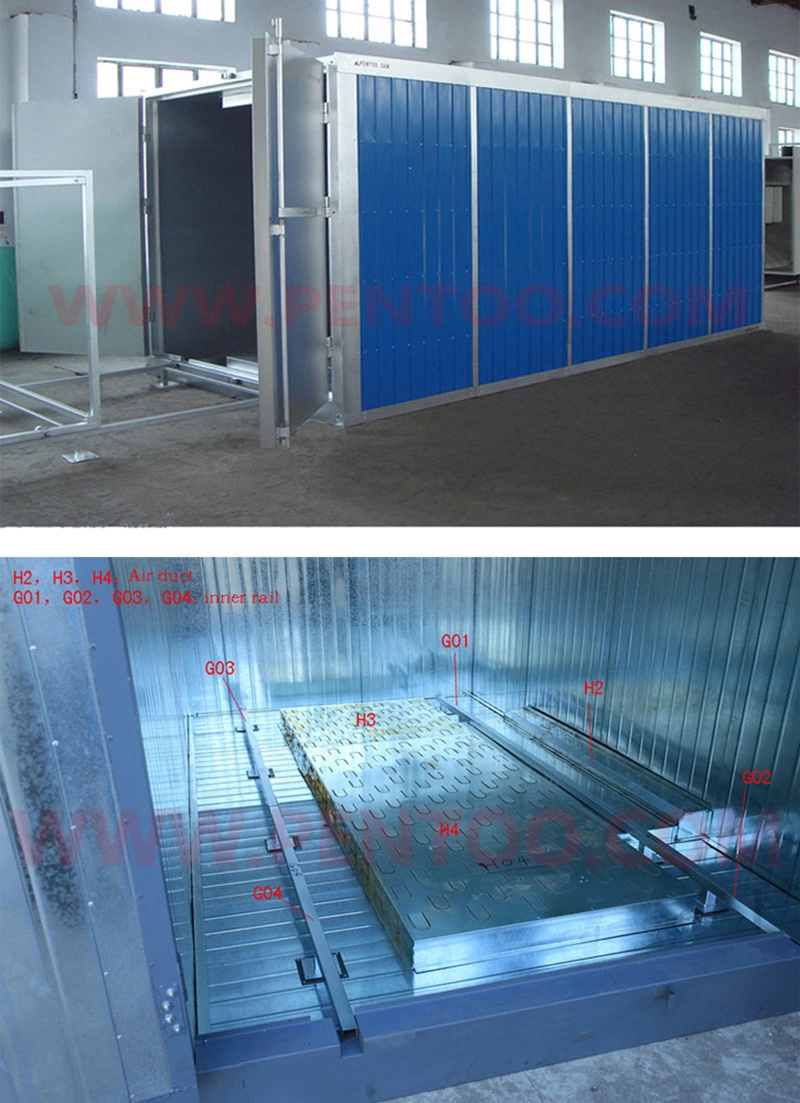

| Electric curing oven | ||

| Assembled Cabin system | - Outsize: 2.4m(H) * 2.3m(W) * 1.9m(L), one-side open - 1 inner rail, 1 outter rail -4 wheels and 2 mudsills for workpiece trailer made by customer | |

| 24kw Full automatic electric heating system | - stainless steel electric heating tube | |

| - temperature and holding time are automatically digital control - The temperature is automatically raised to the set temperature, and then set the time of the heat preservation .Automatic alarm after completion. | ||

The thermal insulation box of assembled curing oven (Suitable for all kinds of heating system)

System of characteristic:

The inside wall of the curing oven is pressure reinforced galvanized steel sheet, which has long life.

The outer wall is pressure groove reinforced electrostatic coating color steel plate, which has beautiful appearance.

The thermal insulation layer adopts the density of 100 kg/cubic meter 100mm rock pressure cotton.

The side wall of the insulation board set the heat residence bridge structure, gives it good heat preservation effect.

Both of the connection of parts and the curing oven insulation box are made by galvanized steel sheet.

There are lots of heat resistance structure on the surface of important connection parts to reduce the heat loss.

Adopts the reasonable assembling structure, the transportation is convenient, the transportation cost is low, the assembling technology is simple, and the heat preservation effect is good.

Gas heating, coal-fire heating and fuel heating curing oven install adjustable air outlet with multiple points uniform cloth, make the airflow in the drying tunnel are reasonable distribution, and the temperature is uniform.

As for far infrared electric radiation heating curing oven, through the reasonable uniform of inside heating element to reducing the temperature difference of each parts.

The curing door adopts the locking structure of imitating containers with user-friendly.

There are tongue-and-groove baffles around the door,on the edge of door, we set hermetic raised lines, the tightness is good.

The gate lock adopts the patent automatic lifting structure, after unlocking, the lock lever will rise automatically, in order to avoid meeting the rail outside the door when opening the door.

The curing oven can be opened on both sides, in order to facilitate the workpiece turnover, increasing the utilization rate of the curing oven, reduce the no-load rate, to avoid the waste of heat loss.