What about PVD?

PVD (Physical Vapor Deposition) is a widely used and advanced surface treatment technology in the world at present. It can really get micrometer coating and pollution-free environmental surface treatment. In a vacuum state, the coating material is vaporized by ion physical method and deposited into a coating on the surface of the product.

PVD coating features:

(1) excellent adhesion: PVD coating has high adhesion and durability. It can be applied to bending at different angles without cracking or spalling. It can be used for inside and outside decorations.

(2) anti-oxidation, corrosion resistance: stable chemical properties, in the normal environment, indoor and outdoor can be antioxidant, not easy to fade, maintain metal glossiness.

(3) increase the surface hardness: the hardness of the film measured by Micro, up to HV2250

The type and thickness of the coating layer

(1) the species of the coating:

PVD coating technology can prepare nitride film (TiN[titanium gold), ZrN [zirconium gold], CrN, TiAlN] and carbide film (TiC, TiCN), and oxide film (TiO, etc.).

(2) the thickness of the film layer:

The thickness of the film is micrometer, and the thickness of the coating film is generally 0.3 u m~0.5 mu

Product Parameters

| Model | RC-1315 | RC-1618 | RC-1820 | RC-2021 | RC-2023 | RC-2040 |

| Chamber | D1300*H1500 | D1600*H1800 | D1800*H1200 | D2000*H2100 | D2000*H2300 | D2000*H4000 |

| Structure | Vertical door,hanging or horizontal cart structure,pumping system, and water cooling system. | |||||

| Vacuum system | sustaining Pump+Mechanical Pump+Roots Pump+Diffiusion Pump+Molecular Pump | |||||

| Measureme | 1set piraning, 1set cold cathode, 1 set diaphragm gauge | |||||

| Power | Medium frequency power, arc power supply,pulse power(bia power,arc power) | |||||

| Ultimate Pressure | 1.0-6.0x10-4Pa,Non-loading cooling | |||||

| Arc Source | 16-24set | 16-24set | 18-26Set | 18-26set | 22-28set | 22-32set |

| 200A | 200A | 200A | 200A | 200A | 200A | |

| Magnetron Power Supply | 1-2set | 1-2set | 2-3set | 2-3set | ||

| Temp | Normal Temperature 450ºC(PID temputure control) | |||||

| Gas | Ar, N2,O2,C2H2,etc | |||||

| Controlling Mothed | Manul auto,touch screen operation,PLC or computer controlled | |||||

| Supply Index | Air pressure 0.5-0.8MPa, whater temperature ≤25ºC,water pressure≥0.2MPa | |||||

| Total Power | 100-125kw 125-145kw 145-165kw 165-185KW 185-200KW 200KW | |||||

| Output Frequency | Valtage 380V, Frequency 50HZ/60HZ | |||||

| Occupation Space | 15-50m² 15-50m² 25-55m² 25-55m² 35-55m² 35-55m² | |||||

Tool hard film coating machine suitable for production enterprises in large quantities of tools (drill bit, milling cutter, broach, tap, gear cutter, etc.), high precision mold (stamping mold, cutting mold, molding mold, injection mold, etc) and other key components on the coating of single/multi-layer hard coating, corrosion-resistant coating and other functional films.

Machine Feature: Tool hard film coating machine has the advantages of fast deposition, high ionization rate, high energy density. Also it is with simple operation, low cost and high productivity.

Kind of Film: TiN ALTiN TiAlS,TiCN AiCrN DLC

Film Advantage: High Hardness, High-wearing, Corrosion Preventive and Stability. The film has longer life and it can make sure better surface of product.

Application Fields: drilling, scraw tap, high speed blade, anti-friction bearing, cutting tool, and other decorative film.

Remark: The configuration of machine can also be devised by customer's request and processed products.

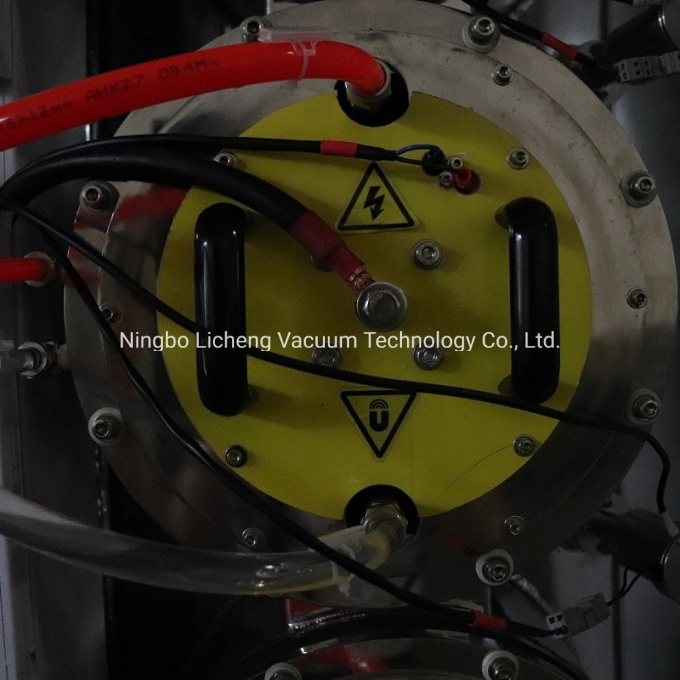

Detailed Images

Our Company

Our Advantage

1.We are PVD coating machine manufacturer

2.We offer Processing Service(we coat the film for clients).

3.We offer free training after you bought our machine

4.We offer online training after the machine got your factory.

5.We have engineers abroad.

The fields of application

1. building hardware bathroom hardware (such as water). The lock of the door.

The door handle.The bathroom,hardware hinges, furniture etc..

2. Watch: can be used for watchcase, strap coating, crystal products.

3. other hardware: leather hardware. Stainless steel tableware.

Spectacle frames, knives, molds and so on

4. large workpiece: automobile wheel hub, stainless steel plate,

signboard, sculpture and so on.

5, stainless steel tubes and plates (all types of surface)

6, furniture, lamps and lanterns, hotel appliances.

7, locks, handles, bathroom hardware, golf head, stainless steel

tableware, utensils and other hardware products plated super hard decorative film.

Our Factory

Our Team

Coating Service Procedure

Package

After-sale Service

FAQ

Q: What is the warranty of your machine?

A:The warranty is one year,the warranty does not include accident,human fault

or improper use,it starts after the equipment arrive at final user's site and

finished installing and testing. Within the warranty period, free maintenance

and repairing services(not including supplying spare parts). Warranty period

is expired, whole life's repairing & system upgrade service and spare parts

would be charged accordingly.

Q: Can we sent some samples for test

A: Sure, Samples are always available for you, but the sample cost

and freight cost should be paid.

Q: Do you think what is the biggest advantage of your factory?

A: As We have three coating service factory,also one factory to make pvd

machine.we can offer 7days free training on pvd technology after you

bought our machine

Q: What's your term?

A1: FOB Ningbo , 30% deposit and 70% balance before the shipment

all by T/T.

A2: After long cooperation, more favorable payment term could be negotiable.